Introduction and Applicability

The Hazard Communication (HazCom) Program outlines the University of Illinois at Urbana-Champaign’s commitment to compliance with the OSHA Hazard Communication Standard as adopted by the Illinois Department of Labor on 9/17/2007. It provides guidance on how to implement the plan for individual campus units (department, division, school, center, institute). The purpose of hazard communication program is to ensure that all hazardous chemicals used in workspaces that are not a typical research laboratory are classified and the information concerning the hazards are transmitted to the employees. The employees also need to be trained to understand the hazards and protective measures to take when using chemicals.

A HazCom Plan is required for units where hazardous chemicals are being used or generated (this could be cleaners, paints, thinners, glues, wood dust etc.) or for any other workplace where employees have a potential for exposure to hazardous chemicals. Each campus unit should identify work areas where non-laboratory exposure to chemicals occurs. The unit head is responsible for ensuring that the requirements of the HazCom Standard are met.

A HazCom Plan is NOT required for occasional use of consumer products such as glues, ink, toner, or detergents, where the exposure is not higher or different than it would be for typical household use. Office use of such consumer products does NOT require participation in the program.

Contact DRS if you think your unit may fall under the HazCom Program and you have not implemented a plan. We will assist you in implementing a plan for your unit. DRS will also perform a hazard assessment and provide initial training.

Implementing the Plan

To implement the program, be familiar with the campus Hazard Communication Plan.

Scan the QR code with your mobile device for the campus Hazard Communication plan

The program is composed of the following elements:

- Plan: The university's hazard communication plan must be readily available for all employees. This plan should be supplemented with any unit specific chemical procedures or Job Hazard Analysis (JHA). This unit specific plan should be updated whenever processes involving new chemical hazards are introduced into units. DRS can assist with the hazard assessment for new procedures.

- Inventory: Units should prepare an itemized list of chemicals present using a product identifier (the product name or number) that is referenced on the Safety Data Sheets. This does not have to include quantities of the chemical. This list must be available for employees to reference.

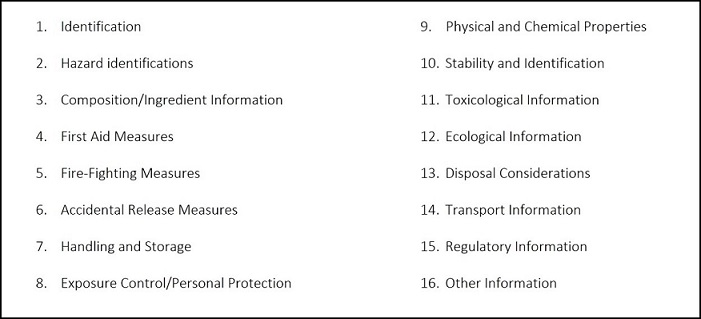

- Safety Data Sheets (SDS): The Hazard Communication Standard requires units to have Safety Data Sheets or SDSs of chemicals in a uniform 16 section format with pictograms for easy hazard identification. Employers must ensure that the SDSs are readily accessible to employees for all hazardous chemicals in their workplace. A back-up copy of SDSs should also be available in case of power outage or other emergencies. Old SDSs of unused chemicals should be archived and kept separate from active SDSs for easy access of active SDSs.

- Labeling: Units must ensure that all chemical containers used in the workplace are appropriately and legibly labeled. Individual labeling is not necessary for stationary process containers, if alternative methods like signs or placards used in the area convey the hazard information. All secondary containers like spray bottles must be labeled with the product identifier, associated pictograms and signal word when applicable.

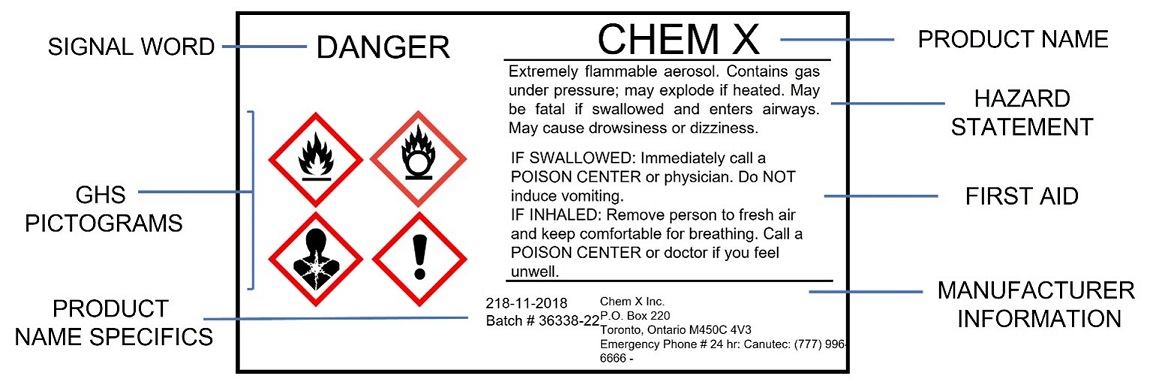

Labeling elements of a primary chemical container

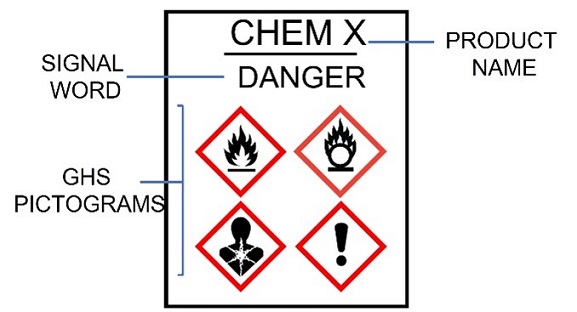

Labeling elements of a secondary chemical container Training: Employees exposed to chemicals should complete the Hazard Communication online training module offered by DRS or an alternative version of the training approved by DRS. Units are required to document the training and provide a copy to DRS during the annual walkthrough. It is highly recommended that this training be part of the onboarding process for new employees. Although this training does not expire, units are encouraged to review the training when new hazards are introduced or as a refresher for effectiveness.

Training should include the following components:

- Details of the university's Hazard Communication Plan.

- Safety Data Sheets of chemicals (including compressed gases) and how to read and understand them.

- GHS symbols that are used as pictograms for chemical labeling and on the SDS.

- Methods used to detect the presence or accidental release of hazardous chemicals like visual appearance, odor, etc.

- Physical, health hazards and hazards not otherwise classified (HNOC) of the chemicals that employees are exposed to.

- Appropriate work practices and measures that can be used to protect themselves from exposure. This includes training employees on unit specific procedures and workplace practices the employer has implemented to reduce exposure including but not limited to:

- Appropriate selection and use of personal protective equipment like gloves, respirators, face shield, etc.

- Emergency equipment checks and maintenance to ensure functionality for effective emergency response in case of minor spills or accidents.

- Work practices including general chemical hygiene, electrical safety, and other practices that contribute to a safe work environment where chemicals are stored and used.

Safety Walkthrough

DRS will evaluate the effectiveness of your hazcom program via safety walkthroughs on an annual basis. During this walkthrough, DRS will discuss any safety shortcomings with the hazcom coordinator of the unit. Units will receive a Hazard Communications Audit Report detailing the walkthrough assessment. Audit reports from DRS are viewed and responded to by logging in to the DRS website. The report serves to document findings and provides a record of how the unit addressed the issues. Units are required to respond with how they addressed the findings in a timely manner (less than two weeks). In cases where findings will take longer than 2 weeks to address, units should response with how they plan to address the issue.

Important Links

- Hazcom training

- OSHA Hazard Communication Standard 1910.1200 https://www.osha.gov/hazcom

- Campus Written Hazard Communication Plan

- Inventory Template

- Training Documentation Form

- PPE Selection Form

- Hazcom Audit Checklist