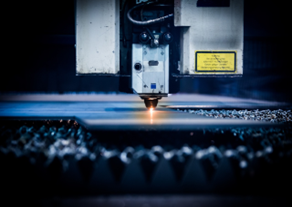

Laser cutters are safe when used as designed with all safety features in place and operable. These safety features include interlocks to avoid accessing the laser, filtration and ventilation systems to remove harmful contaminants, standard operating procedures/manuals, and training.

Using a laser cutter can become hazardous due to the potential for fires from the intense heat generated during cutting and/or the ignition of flammable materials. Additionally, the cutting process and heat can result in the generation of hazardous airborne contaminants.

Basic Safe Operation Concepts

- Always operate the units with the installed safety features in place and functioning as designed. Do not operate a unit that is damaged, malfunctioning, or has openings that are not protected.

- Inspect the unit before each use. Follow manufacturer’s guidance for required cleaning.

- Ensure filtration materials are regularly changed/cleaned as directed by the manufacturer.

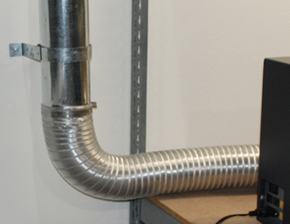

- Ensure ventilation routes are properly installed and free of obstructions. Additionally, ventilated air should not be routed to public or occupied areas.

- Follow manufacturer recommendations regarding the types of materials that can be cut. Do not cut prohibited materials. This could result in unplanned fires and or the generation of highly toxic airborne contaminants.

- Prominently display a list of materials approved for cutting. Emphasize that only the listed materials may be cut, no additions without approval from the laboratory’s supervision.

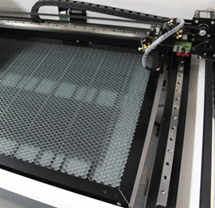

- Maintain the unit in a clean manner; including, ensuring filters are clean, and work surfaces, especially the cutter deck/operating surfaces are free from clutter, debris, and items that could ignite or catch fire.

Interlocks

Laser cutters must be equipped with interlocks that prevent interaction with the enclosed laser. The interlocks allow the laser cutter to be classified as a Class 1 system, the lowest, inherently safe classification; however, the internal laser will be at a higher classification, normally Class 3B or 4 and would require a higher level of protection and training if operated independently.

Filtration and Ventilation

When installed the laser cutter must have secure, dedicated ventilation as prescribed by the manufacturer to remove air contaminants. If the unit is equipped with a filter the filter system must be maintained, including periodic cleaning and change-out of filters according to specified schedules.

Training and Use

A training document or SOP must be prepared (alternatively, manufacturer’s documents may be utilized), and all users must receive awareness and operational training before use. Document all users training and maintain a log of users. The operating procedure detail should also include:

-Instructions on maintaining the unit in a clean manner. For example, filter/ventilation system maintenance and cleaning, and minimizing/removing clutter that may ignite and cause fires.

-What materials can safely be cut. Safety data sheets (SDS) should be obtained for materials that may be utilized in the system.

-What materials should NOT be cut. Examples include:

| Material | Hazard | Potential Consequence |

|---|---|---|

| Poly-Vinyl-Chloride (PVC); Vinyl | Can emit chlorine gas when cut | Gases potentially corrode the optics, cause the metal of the machine to corrode, or affect the internal parts. |

| Thick (>1mm) Polycarbonate or Lexan® | Cuts very poorly, discolors, may ignite | The window of the laser cutter is made of polycarbonate because polycarbonate strongly absorbs infrared radiation; the frequency of light the laser cutter uses to cut materials. It is ineffective at cutting polycarbonate. |

| Acrylonitrile-Butadiene- Styrene (ABS) | Emits cyanide gas and melts | Does not cut well. Melts and has a high chance of igniting and leaving behind melted deposits on the vector cutting grid. |

| High Density Polyethylene (HDPE) | Cuts poorly, may ignite and melts | Melts. Leaves deposits. |

| Polystyrene and Polypropylene Foam | May ignite | Ignites, melts, and only thin pieces can be cut. A top cause of laser cutter fires. |

| Fiberglass | Emits fumes | Mix of two difficult to cut materials. Glass (etch, no cut) and epoxy resin (fumes) |

| Coated Carbon Fiber | Emits noxious fumes | Mix of two materials. Thin carbon fiber mat can be cut, with some fraying - but not when coated. |

| Any powder | Compressed air will displace the material. | |

| Flammable/Combustible liquids | Liquids of this type should not be present in any materials cut with the laser cutter. The laser beam will act as an ignition source likely resulting in a flame and/or fire. |