Policy Statement

The following procedures were developed to protect the Maintenance Division personnel of Facilities and Services (F&s;S) and the University of Illinois at Urbana-Champaign laboratory occupants from potential exposure to hazardous materials while servicing exhaust systems. This policy was reviewed and approved by the University of Illinois at Urbana-Champaign Chemical Safety Committee, December 2004.

Scope

This policy applies to all work that requires servicing and repairing or dismantling of a chemical fume hood, entering or removing duct work, entering the fan housing, changing filters, shutting off fans or any other maintenance that requires entering the inside of the exhaust system.

Special precautions are usually not required when servicing equipment that is outside of the chemical fume hood cabinet and/or outside of the potentially contaminated air stream. For example, belts and pulleys may be serviced, vibration isolators may be adjusted and lamps may be replaced on many chemical fume hoods without entering the interior of the hood or exhaust duct.

Program Components

- Responsibilities

- Special Operating Procedures

- Procedures for Servicing a Chemical Fume Hood

- Procedures for Servicing a Dedicated Exhaust System Fan

- Procedures for a Shutdown of Multiple Chemical Fume Hoods

- Maintenance Procedures

Responsibilities : Facilities and Services (F&S)

- When service requires that a chemical fume hood or other local exhaust system be shut down, F&S personnel must communicate to the designated laboratory supervisor the need for service and obtain permission to shut down the chemical fume hood and/or the local exhaust system. In addition, communicate to the designated laboratory supervisor the time and duration of the shut down. If a laboratory supervisor is not available, contact the building manager or department administration to obtain permission to shut down the chemical fume hood or other local exhaust system.

- F&S personnel must not shut down the chemical fume hood or local exhaust systems without permission from an authorized person and until all hazardous materials in the chemical fume hood and adjacent work area are secure.

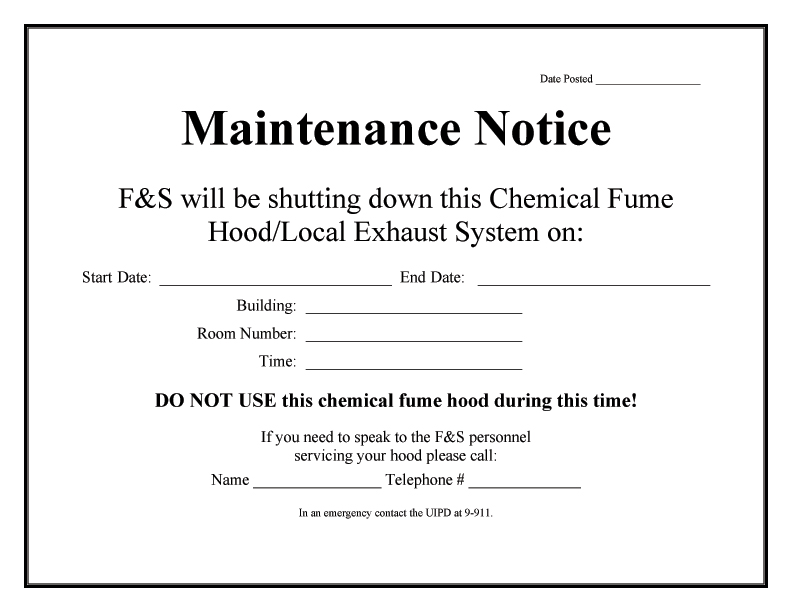

- Before an exhaust system will be shut down, F&S personnel must complete and post a "Maintenance Notice" on the sash of the chemical fume hood. If the exhaust system being serviced provides ventilation for an entire room, the "Maintenance Notice" should be placed on the door to the room.

- F&S personnel shall not alter, move or remove laboratory chemicals or equipment.

- F&S personnel must perform work in a manner consistent with established F&S safety procedures and wear the appropriate personal protective equipment (see Section 6 Maintenance Procedures).

Laboratory Supervisor

- When work must be done inside of the exhaust system, the laboratory supervisor must confirm that hazardous materials are secure and will not be used for the duration of the service work.

- As appropriate, the laboratory supervisor must provide a work area in the laboratory that is cleared of laboratory chemicals and equipment. F&S personnel shall not alter, move or remove laboratory chemicals or equipment.

Special Operating Procedures

- Radioisotope Hoods. If work is scheduled for a chemical fume hood inside a laboratory posted with a "Caution Radioactive Materials" sign, F&S personnel should contact the Division of Research Safety (DRS) Radiation Safety Section (333-2755) and request a survey to certify that hood contamination is below applicable limits. If contamination is below applicable limits proceed as outlined in Section 6 Maintenance Procedures. If contamination is above the applicable limits, the DRS Radiation Safety Section will specify the special procedures to be followed.

- Perchloric Acid Hoods.If work is scheduled for a perchloric acid hood, F&S personnel should contact the DRS Chemical Safety Section (333-2755). The system will be tested for the presence of perchlorates. If perchlorates are not present or are present at acceptable levels, proceed as outlined in Section 6 Maintenance Procedures. If perchlorates are present at greater than acceptable levels, proper precautions shall be taken to wash down the system with water until the levels are acceptable. After safe levels are reached, proceed as outlined in Section 6 Maintenance Procedures.

- Biological Safety Cabinets. If work must be conducted inside contaminated spaces of a biological safetycabinet such as the plenum, blower, or high efficiency particulate air filter (HEPA) compartment, F&S personnel should contact the DRS Biological Safety Section (333-2755).

- Heat Recovery Coils. Work to be scheduled for heat recovery coils should follow the guidelines as outlined in Section 6 Maintenance Procedures. If the heat recovery coil work involves interrupting/reducing airflow to exhaust systems servicing research facilities, the applicable procedures as outlined in Section 4 Procedures for Servicing a Dedicated Exhaust System Fan and Section 5 Procedures for a Shutdown of Multiple Chemical fume hoods shall be followed. Prefilters must be carefully removed and sealed in heavy polyethylene bags. Contact DRS Chemical Safety Section (333-2755) for disposal options.

Procedures for Servicing a Chemical Fume Hood

- When a chemical fume hood is suspected of not functioning properly, the F&S Service Office should be notified immediately at 333-0340. In order to avoid inadvertent use of the chemical fume hood, F&S will post a "Maintenance Notice" on the sash of the chemical fume hood. The notice should be posted in the lower, center area of the sash so that it is easily visible.

- It is the responsibility of the laboratory supervisor to ensure that the chemical fume hood is prepared prior to maintenance by F&S. If work by F&S is required to be performed on the inside of the chemical fume hood, the laboratory supervisor must ensure the removal of all hazardous materials and equipment. If necessary, the laboratory supervisor has responsibility for the decontamination of the interior of the chemical fume hood. All residues must be cleaned from the walls, the work surface, and the sash of the chemical fume hood with an appropriate solvent or cleaning solution. DRS (333-2755) may be consulted regarding appropriate decontamination procedures.

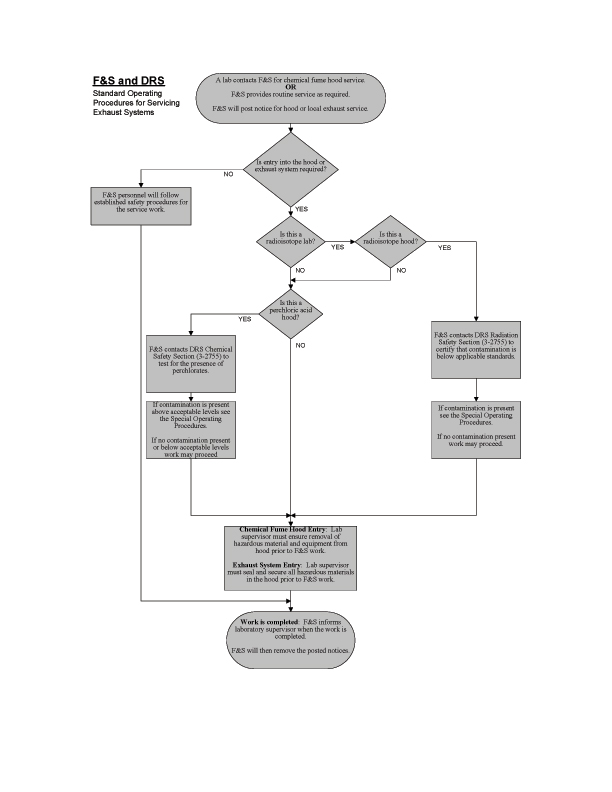

- F&S personnel may use the attached flowchart to determine if DRS should be consulted prior to servicing the chemical fume hood.

- The chemical fume hood will be scheduled for service as quickly as possible after receiving clearance from the affected department's administration.

- Once the service is completed, F&S personnel will perform an airflow check with a calibrated (e.g., Shortridge) hand-held portable meter to confirm that the chemical fume hood is functioning properly (currently the airflow check by F&S is not conducted for fan belt replacements). If the chemical fume hood is functioning within the campus guidelines, the "Maintenance Notice" will be removed and a new chemical fume hood inspection sticker will be applied by F&S.

- If the chemical fume hood repair is determined to be beyond the scope of services available through F&S or if the airflow check indicates inadequate airflow, the "Maintenance Notice" will be updated to reflect the new maintenance schedule and once again be posted on the chemical fume hood. It is F&S's responsibility to follow-up with the laboratory supervisor and the affected department's administration to make sure the user understands the problem identified and the options available for repair.

Procedures for painting a chemical fume hood

- Laboratory supervisors/department administrators may request that a chemical fume hood be painted by completing a service request with F&S.

- It is the responsibility of the laboratory supervisor/department administration to ensure that the chemical fume hood is prepared prior to maintenance by F&S. The laboratory supervisor/department administration must ensure the removal of all hazardous materials and equipment. If necessary, the laboratory supervisor/department administration must ensure that the interior of the chemical fume hood is decontaminated. All residues must be cleaned from the walls, the work surface and the sash of the chemical fume hood with an appropriate solvent or cleaning solution. DRS (333-2755) may be consulted regarding appropriate decontamination procedures.

- F&S personnel may use the attached flowchart to determine if DRS should be consulted before proceeding with the chemical fume hood painting.

- F&S painters will post a "Maintenance Notice" on the sash of the chemical fume hood in order to avoid inadvertent use of the chemical fume hood. The notice should be posted in the lower, center area of the sash so that it is easily visible.

- The hood will be scheduled for painting.

Procedures for Servicing a Dedicated Exhaust System Fan

These procedures shall be followed when a dedicated exhaust fan serves a chemical fume hood or a small number of ganged chemical fume hoods within one laboratory.

- F&S will communicate to the laboratory supervisor the need for service and the duration of the fan shut down.

- F&S will obtain permission to shut down the chemical fume hood(s) and/or the local exhaust system at an agreed upon date and time.

- Except for emergency situations, F&S personnel will post the "Maintenance Notice" on the affected chemical fume hood(s) a minimum of three days prior to the scheduled shutdown. The notice should be posted in the lower, center area of the sash so that it is easily visible. The affected hood(s) will be out of service during the period indicated on the notice regardless of whether or not the fan is actually operating. F&S will not post the "Maintenance Notice" on chemical fume hoods located inside cleanrooms. The cleanroom coordinator will be responsible for posting an appropriate maintenance notice on the affected hood(s).

- The laboratory supervisor must ensure that hazardous materials have been secured and no operations/experiments, including closed systems, shall be conducted in the chemical fume hood(s) for the duration of the maintenance as indicated on the posted notice.

- If the fan to be worked on is located near hood exhaust stacks, which do not have a 7 to 10 ft. extension, those fans must also be turned off. If this is not possible, F&S personnel must wear an appropriate respirator and safety goggles supplied by F&S Operations.

- Once the service is completed, F&S personnel will perform an airflow check with a calibrated (e.g., Shortridge) hand-held portable meter to confirm that the chemical fume hood is functioning properly (currently the airflow check by F&S is not conducted for fan belt replacements). If the chemical fume hood is functioning within the campus guidelines, the "Maintenance Notice" will be removed and a new chemical fume hood inspection sticker will be applied by F&S.

- If the airflow confirmation indicates that there is inadequate airflow, the "Maintenance Notice" will be updated to reflect the new maintenance schedule and remain in place on the chemical fume hood. It is F&S's responsibility to follow-up with the laboratory supervisor and the affected department's administration to make sure the user understands the problem identified and the options available for repair.

- Any questions should be directed to the F&S personnel listed on the notice at the number provided.

Procedures for a Shutdown of Multiple Chemical Fume Hoods

When maintenance work on a chemical fume hood fan is required, it may be necessary to schedule a shutdown of an entire bank of hoods.

- F&S will contact and communicate with the administration of the affected department(s) to confirm shutdown dates and times.

- The department administration will notify the affected researchers of the need for the fan maintenance and the date and time the fan maintenance will occur.

- Except for emergency situations, F&S personnel will post the "Maintenance Notice" on the affected chemical fume hoods a minimum of three days prior to the scheduled shutdown. The affected hoods will be out of service during the period indicated on the notice regardless of whether or not the fan is actually operating. The notices will be consecutively numbered for accurate removal after completion of the work. F&S will not post the "Maintenance Notice" on chemical fume hoods located inside cleanrooms. The cleanroom coordinator will be responsible for posting an appropriate maintenance notice on the affected hoods.

- For chemical fume hoods posted with the "Maintenance Notice" the laboratory supervisor must ensure that hazardous materials have been secured and no operations/experiments, including closed systems, shall be conducted in the chemical fume hood for the duration of the maintenance as indicated on the posted notice.

- Immediately prior to the maintenance work being performed, a departmental or laboratory representative will conduct a visual inspection to ensure that no experimental operations are ongoing in the chemical fume hoods posted with the "Maintenance Notice." All violations must be corrected by the chemical fume hood user. The departmental or laboratory representative will then notify F&S when the inspection is complete and/or the violations have been corrected.

- If the fan to be worked on is located near hood exhaust stacks, which do not have a 7 to 10 ft. extension, those fans must also be turned off. If this is not possible, F&S personnel must wear an appropriate respirator and safety goggles supplied by the F&S Operations.

- Once the maintenance work is completed, F&S personnel will perform an airflow check with a calibrated (e.g., Shortridge) hand-held portable meter to confirm that the chemical fume hoods are functioning properly (currently the airflow check by F&S is not conducted for fan belt replacements). If the chemical fume hoods are functioning within the campus guidelines, the "Maintenance Notice" will be removed and a new chemical fume hood inspection sticker will be applied by F&S.

- If the airflow confirmation indicates that there is inadequate airflow, the "Maintenance Notice" will remain in place on the affected chemical fume hood. It is F&S's responsibility to follow-up with the laboratory supervisor and the affected department's administration to make sure the user understands the problem identified and the options available for repair.

- Any questions should be directed to the F&S personnel listed on the notice at the number provided.

Maintenance Procedures

- Disposable nitrile gloves, chemical splash goggles and chemical resistant coveralls (Tyvek™) should be worn if there is a potential for contact with internal chemical fume hood/local exhaust components. Where exhaust systems are suspected of being pressurized an appropriate respirator and chemical splash goggles shall be worn to prevent exposure to potentially contaminated exhaust air.

- If cleaning internal chemical fume hood surfaces with all-purpose cleaners (e.g., Soilax®, TSP) wear long length chemical resistant reusable gloves with folded cuffs, chemical splash goggles and chemical resistant coveralls (Tyvek™).

- When working around sharp objects like sheet metal, wear appropriate outer work gloves in addition to inner disposable nitrile gloves. If the outer work gloves are suspected of being contaminated they shall be disposed of at the completion of each workday.

- When performing work near hood exhaust stacks, which do not have a 7 to 10 ft. extension, arrangements should be made to shut down the associated exhaust fans for the duration of the work. If this is not possible, F&S personnel must wear an appropriate respirator and chemical splash goggles.

- Do not eat, drink, or apply cosmetics or medication while in the laboratory.

- Do not touch, move or handle containers of any chemicals or materials in a laboratory. If containers or equipment need to be moved, ask the laboratory supervisor to relocate them.

- After work is completed, the nitrile gloves should be discarded and hands should be washed with soap and water.

- Personal hygiene is important. Hands should always be washed with soap and water at the completion of any work.

- Remove the applicable "Maintenance Notice" posts after work has been completed.

- When applicable, perform airflow check with a calibrated (e.g., Shortridge) hand-held portable meter to confirm that the chemical fume hood is functioning within the campus guidelines. Apply new chemical fume hood inspection sticker.